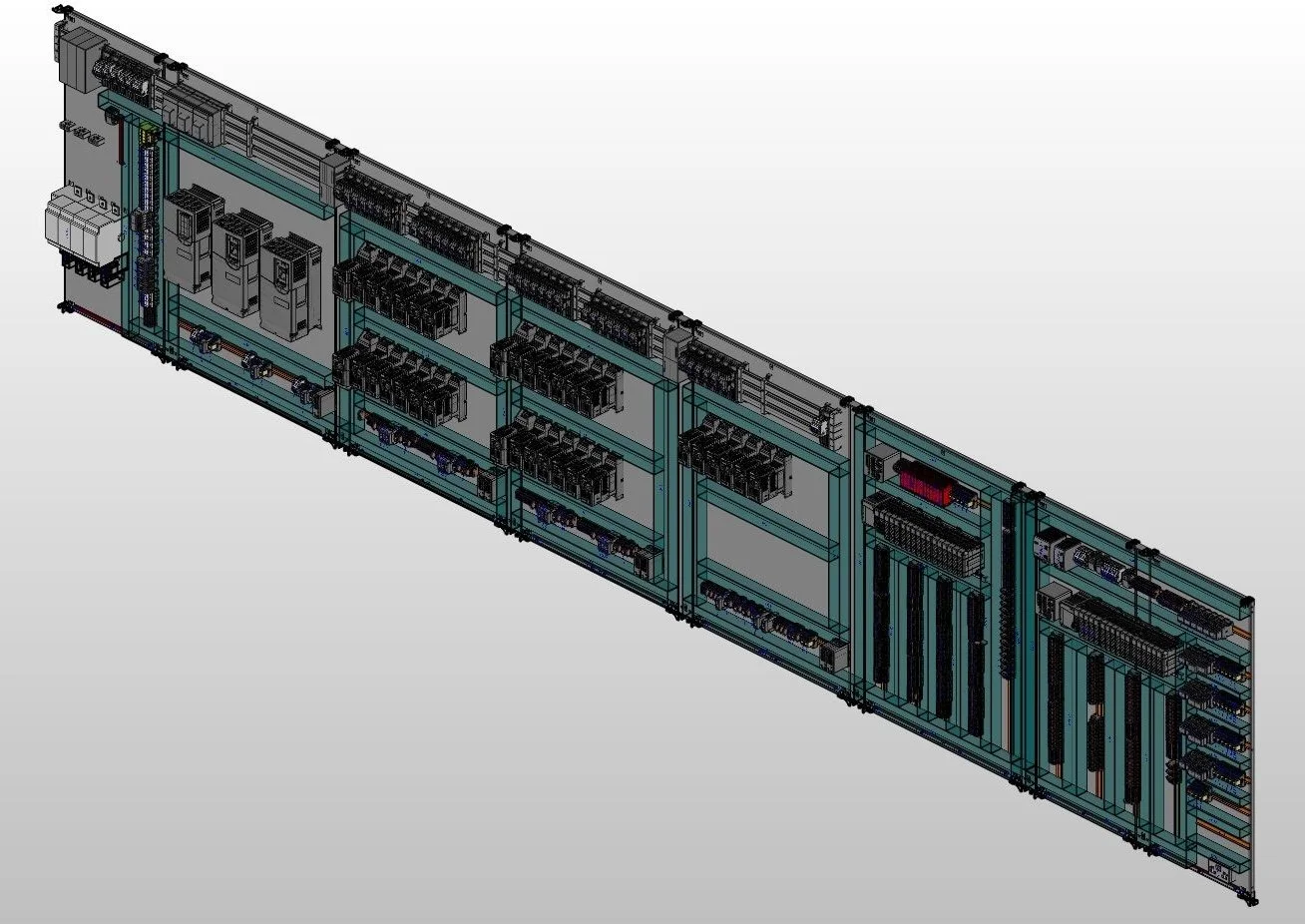

Large-Scale Control Panel Design for Flour Transfer System

Sectors: Materials Handling / Food & Beverage

Scope: Design & Manufacture of Large Process Control Panel

Platform: Rockwell / Allen Bradley

Tools: EPlan Design, Rittal Busbar, Modular Layout

The Challenge

A leading materials handling systems integrator needed a specialist partner to design and manufacture a full-scale process control panel for a UK-based bakery’s flour transfer system. The installation featured multiple silos, mixers, sack tip stations, ingredient pods, and vessels - all part of a large-scale pneumatic conveying system for high-volume bread production.

The solution had to meet strict food safety standards while being robust, maintainable, and scalable for future plant development.

Our Solution

Working in close collaboration with the system integrator, we designed and delivered a comprehensive control system that included:

One large stainless steel process control panel

Multiple remote ‘Silo Fill’ panels and HMI stations

Full PLC, VSD, and HMI software development on a Rockwell/Allen Bradley platform

Custom graphics and plant overviews on operator HMIs for intuitive use

Designed for Scalability and Efficiency

Our modular design approach ensures that the functionality and layout of the panel remain logical and serviceable. Key features include:

Functional zoning of inverter drives and motor starters to simplify field wiring

Use of a Rittal Busbar system for efficient LV power distribution

Panel layout designed for easy maintenance and future expansion

This project also demonstrates the scale and complexity of the control systems we can deliver from our in-house workshop.

Precision Engineering with EPlan

Every aspect of the panel was designed using EPlan, our industry-standard proprietary CAD package. We provided:

Detailed 2D and 3D schematics

Full documentation for installation and operation

Pre-build and post-install photography to showcase quality and accuracy

This project highlights our ability to deliver highly engineered, food-safe control panels for complex process environments. By integrating hardware, software, and modular design thinking, we enabled the client to launch a critical new production system with confidence and ease of ongoing support.