Future-Proofing Production for a Food and Beverage Client

Sector: Food and Beverage

Scope: Full Electro-Mechanical Upgrade (Including Full Machine Re-Wire)

Technology: Siemens PLC, HMI, VSD & Servo

Impact: Improved Safety, Longevity & OEE

The Challenge

A leading Food and Beverage client in Harrogate required a comprehensive upgrade to four critical production machines responsible for manufacturing speciality tea products. Their existing Tecno T2 string, tag, and envelop machines faced growing risks due to control system obsolescence and outdated guarding that no longer met modern safety standards.

The client needed a partner who could modernise their systems while preserving the original mechanical setup, integrating new technologies without disrupting day-to-day operations.

Our Solution

We delivered a turnkey electro-mechanical upgrade covering all electrical, software, and mechanical elements. Two of the four machines have now been fully upgraded, with the remaining scheduled over the next 12 months.

Key highlights of our work include:

Complete rewire of each machine

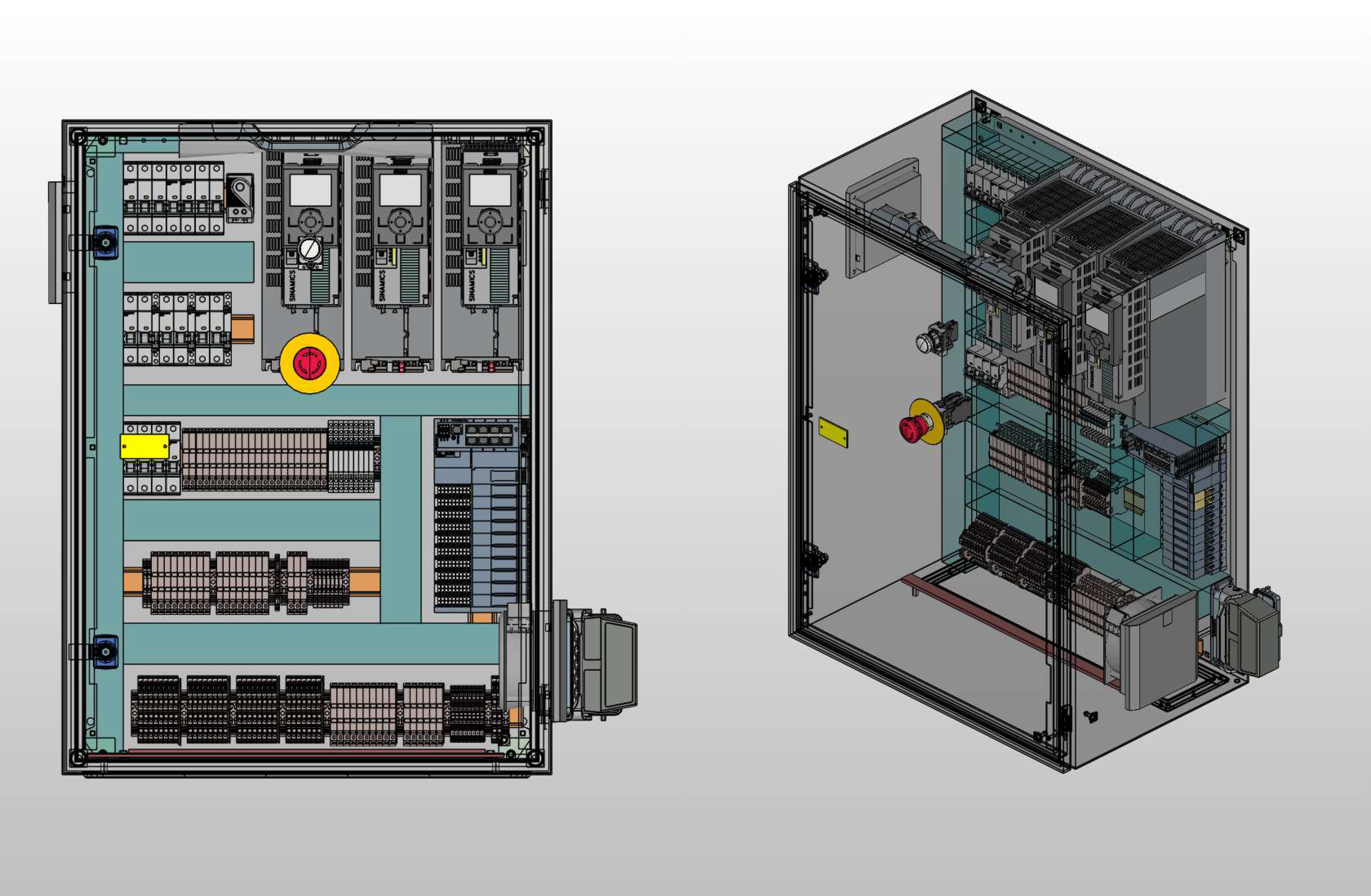

Installation of new control panels designed to fit the existing footprint

Integration of latest Siemens PLCs, HMIs, VSDs, and Servo technology

Custom-built linear stacker upgrade, now Servo-controlled

Engineering drawings completed in EPlan, enabling precise execution and documentation

3D models and photographs of panels shared at both pre-build and post-install stages

Safety & Compliance First

Each upgrade was designed in accordance with ISO 13849-1 & -2:2023 standards, ensuring modern compliance and operator safety.

One machine, in particular, required a complete guarding overhaul. We replaced sagging aluminium frames and Lexan sheeting with:

A stainless steel framework

Durable Lexan panels

Vented aluminium sections positioned above heating elements

This resulted in a robust, heat-resistant, and food-safe guarding solution that is now regarded as the benchmark for other machines in the production hall.

Results & Outcomes

The objective wasn’t just longevity, it was also performance. The new control systems have dramatically improved operator experience and are expected to show a marked increase in OEE (Overall Equipment Effectiveness).

We have requested line performance data from the client, and early indicators suggest a significant uplift in reliability and productivity post-upgrade.

As the remaining upgrades are rolled out, this project will serve as a blueprint for how to modernise legacy food production equipment without full machine replacement.